MOQ:

Default

MOQ:

Default

Port:

Tianjin

Port:

Tianjin

Packaging:

Customizable

Packaging:

Customizable

Lead Time:

Default

Lead Time:

Default

Size:

Default Size

Size:

Default Size

Color:

Default Color

Color:

Default Color

Centrifugal Compressor Advantages:

GDC series gear-driven centrifugal compressors, centrifugal blowers, centrifugal process compressors (a variety of media) are widely used in a variety of industries with high flow supply and continuous operation requirements.

• flow range: 40~ 1500 m3/min

• Working pressure: 1~40 bar

• Motor power: 100~ 14000 kW

Turbo (centrifugal) compressor specifications 130-9100kW

|

Model |

Air Flow M3/min |

Pressure Bar |

Power (KW) |

Dimension LxWxHmm |

Weight(Kg) |

|

GDC-60 |

40-80 |

1-10 |

100-500 |

2950X1660X2100 |

5000-9000 |

|

GDC-150 |

80-180 |

1-12 |

185-1150 |

4100X2400X2400 |

7000-11000 |

|

GDC-250 |

180-280 |

1-15 |

300-1900 |

4800X2200X2600 |

8000-14000 |

|

GDC -400 |

280-400 |

1-20 |

450-3000 |

5300X2880X3000 |

9000-20000 |

|

GDC-800 |

400-800 |

1-35 |

650-7000 |

6200X3500X3800 |

15000-35000 |

|

GDC-1500 |

800-1500 |

1-40 |

1250-14000 |

7200X5000X4800 |

20000-50000 |

We can customize the equipment according to the actual demand data of users. This selection table is for reference. For custom design according to actual flow and pressure requirements, please refer to the pre-sales technical communication.

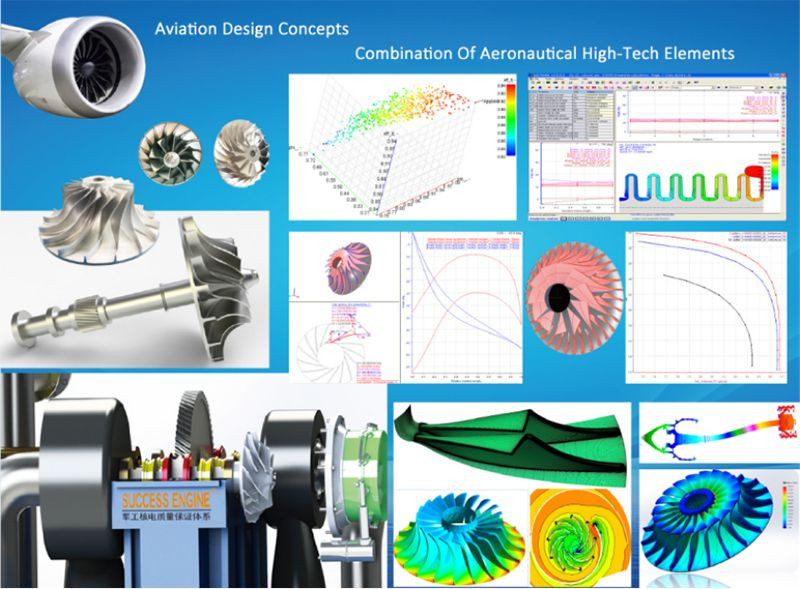

Aeronautical Design Concept-Impeller

Using NASTRAN, ANSYS, Abaqus and other finite element analysis software, the impeller and blade are subjected to one-dimensional geometric and thermal design, two-dimensional flow path design, three-dimensional blade design and strength check. The simulation can determine whether the impeller design meets the design standards of the aero-engine, and can predict the service life of the impeller. To create a highly efficient aero-grade impeller with the best power-to-energy ratio.

High-Speed Tiltable Tile Bearings

Horizontal split tiltable tile bearing made of ISI 1040 carbon steel (inner layer) and pasteurized alloy (surface) material, when the speed load changes, the bearing tilting block is automatically centered, this automatic adjustment function can ensure the smooth operation of the machine.

Aviation Standard High-Speed Gearbox

Horizontal split gearbox structure, using aviation standard processing, manufacturing, commissioning, inspection, built-in high-speed forging alloy steel precision helical gear, horizontal center divides the cylinder into two halves, bolt connection, m modular structure design, easy maintenance and repair.

Highly Efficient Removable Cooler and Air Intake Regulation

The cooler is separated from the gear box, and the lubrication system is perfectly separated from the compressed air to ensure 100% clean and oil-free compressed air. Detachable cooler with precision fit of tube bundle and finished casing, effectively improve the heat exchange rate between compressed air and water and reduce the consumption of cooling water.

By adjusting the impeller inlet guide vane installation angle, the airflow pre-turn can be adjusted in the range of 70-105%.

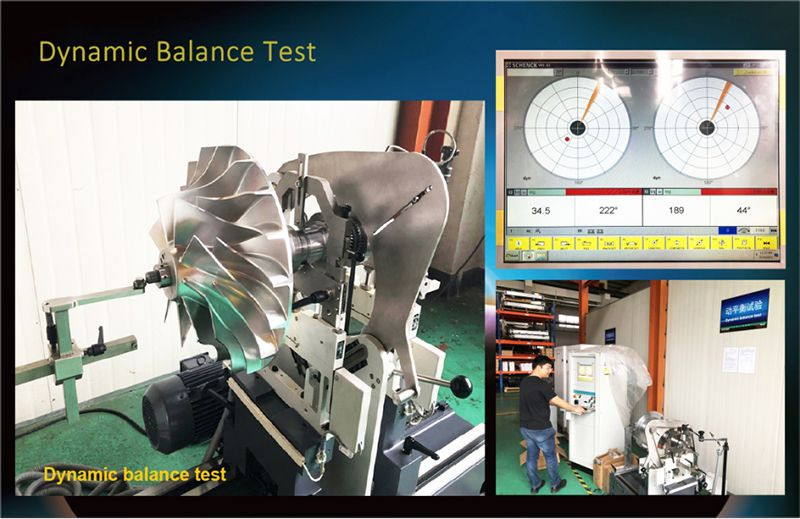

Impeller Dynamic Balance Test

Advanced dynamic balancing test equipment is used to conduct strict dynamic balancing tests on each impeller and shaft assembly under the requirements of the "Dynamic Balancing Test Procedure" to ensure the balance and stability during high-speed operation.